Gearlab Engineer Designs a Device to Test Stress on a Paddle

By Declan J. Nowak

What is the mechanism you created?

I designed an Arduino powered force sensor that recorded the force exerted by a paddler’s hands on a paddle. An Arduino is a small lightweight microcontroller that is perfect for data recording applications because it is capable of recording information to an SD card. The device used two force sensors wired to the Arduino (shown in the images below). The force sensors were mounted on moldable plastic frames to fit around a forefinger and thumb. While the sensor would work without a frame to hold it, the force sensor delivers better results when it makes contact between two hard surfaces (paddle and frame), rather than one hard surface (the paddle) and a compressible surface (skin).

What is the premise you hope to achieve with this mechanism?

The goal of the sensor is to measure the force of water on the blade of the paddle. Initially, I tested under “ideal paddling conditions”, which would be a kayaker performing a standard Greenland stroke in calm weather/water conditions. This measurement under ideal conditions will act as a control value to compare the stress on a paddle during rougher water conditions and more strenuous strokes.

Since the blade of the paddle is submerged in the water, it experiences a distributed load from the water, which is challenging to accurately measure. The easiest way to measure this force is through force analysis, which requires identifying the forces applied by the paddler’s hands to calculate the force on the blade of the paddle. Using the sensor, I was able to determine the maximum force a paddler is likely to apply in ideal paddling conditions. With this knowledge, we can compare the results of testing a paddle in many conditions (various strokes and water conditions) to the results recorded in a controlled environment. Knowing the stress point at which a paddle will break in controlled lab tests, and what the average force of a paddle stroke is, Gearlab can ensure that every paddle will handle tough conditions and more than meet the customers’ expectations.

How did you conduct testing?

After programing and wiring the sensor, I attached the frames to my hands and placed the Arduino in a dry bag. I proceeded to paddle around a cove for several minutes while I performed different types of strokes. I used a Greenland forward paddling stroke, brace strokes, and sweep strokes to simulate the standard usage of the paddle. While I paddled, the data was recorded on an SD card. I subsequently downloaded the data onto a spreadsheet and calculated the force on the blade of the paddle for each stroke and graphed it.

What were the results of your testing?

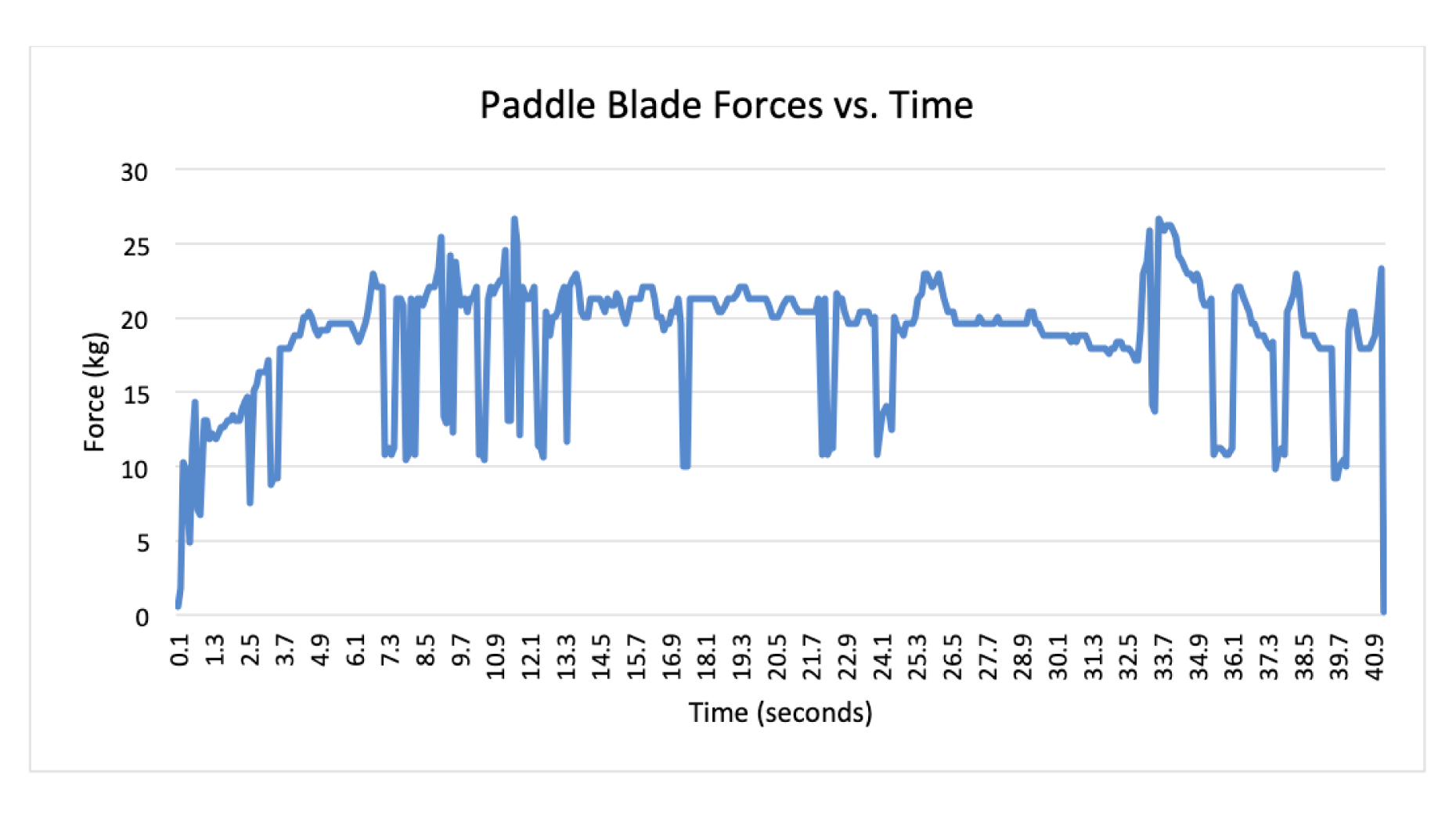

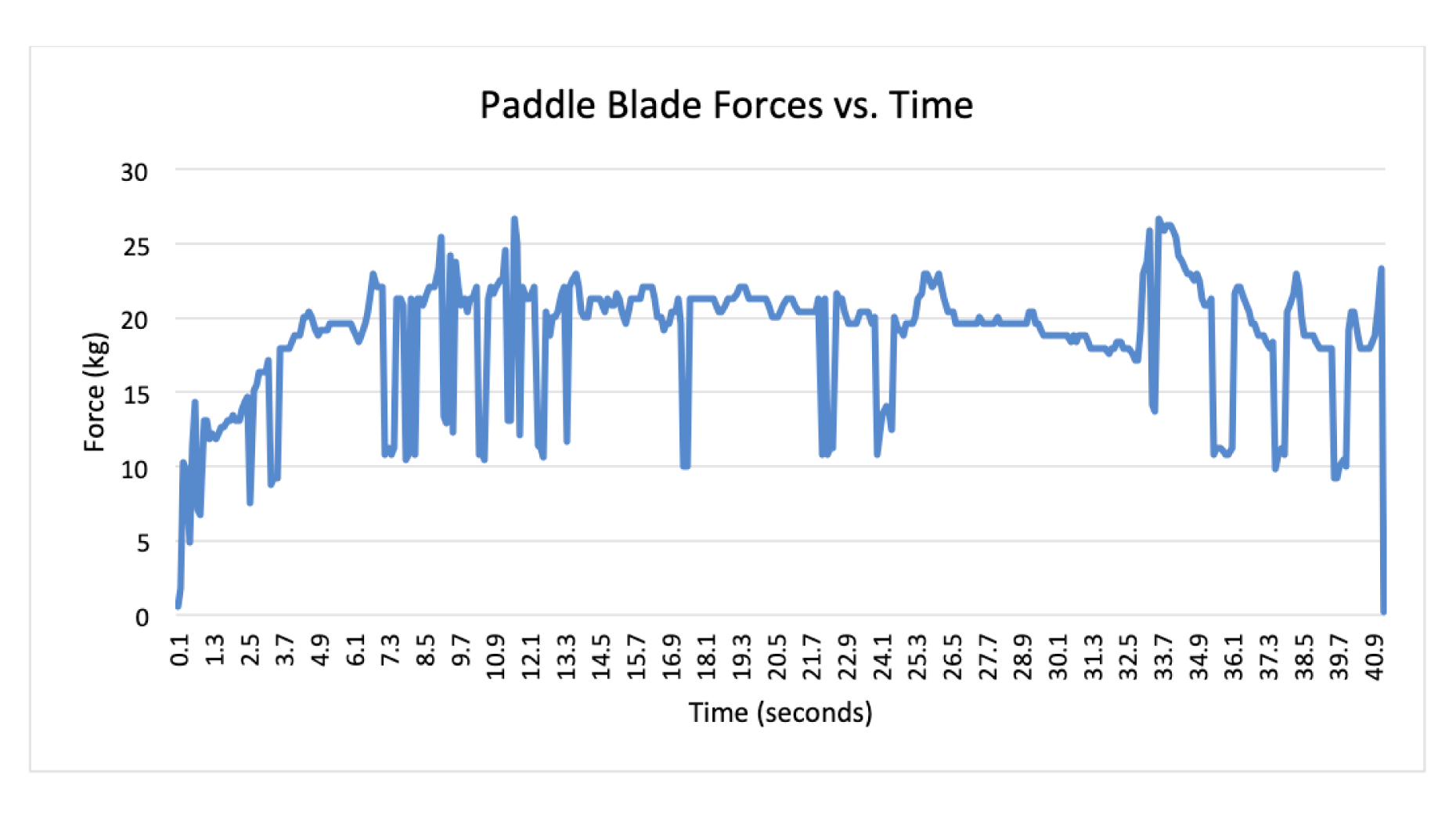

After running the test and calculating the force on the blade of the paddle, I graphed the force to see how it changed as the paddle was used. Each data point on the graph was obtained every tenth of a second. The data shown in the chart represents about 41 seconds of paddling. The data used was the middle 41 seconds of the total 3 minutes of paddling, to exclude the initial force exerted when launching or the deceleration of force when stopping. I determined from the testing and the force analysis that the maximum force was 26.7 kg on the blade of the paddle. From separate lab tests, we already knew that the paddle could easily withstand 50 kg of force in a standard stroke. It required over 70 kg of force during a sweep stroke to break a paddle during laboratory testing. A sweep stroke generates greater stresses within the paddle than a standard paddle stroke since the force is applied at a greater distance from the paddler’s hands. This shows that the maximum force of the paddle is more than double the maximum force on the paddle under normal operating conditions.

*To simplify the graph, no data is recorded when the sensors registered a force of zero.

**While the analysis states that the units of kilograms are a force, the paddle is actually moving the mass of water. The force on the paddle will depend on how fast the paddler is accelerating. For the purposes of this experiment, I assumed that the paddler’s acceleration was the same as the acceleration due to gravity—which is significantly more than the rate a paddler would be accelerating.

How does this serve the consumer?

Gearlab can utilize these results to better serve the consumer by continuing to test their existing paddles to ensure that they will meet the consumer’s expectations. Concrete understanding of the force that a paddle can withstand will assist Gearlab in developing paddles that will withstand all paddling conditions. The idea for this project arose when Gearlab engineers realized that we didn’t know exactly how much force is applied to the paddles during various water and stroke conditions. The best way to begin testing the paddles was to utilize ideal paddling conditions to determine the baseline (“control value”) of stress exerted on a paddle in use. With this information, Gearlab can now stress test their paddles in a controlled way to make sure each paddle that is shipped out will more than meet the customers’ expectations.

How does this serve the brand and product development?

While each kayak paddle company has their own internal standards for product development, Gearlab is working toward establishing a universal standard. This new standard will allow for the consumer to compare the strength of paddles manufactured by different companies, the strength of various lengths and widths of Greenland paddles, and even compare the strength of different types of paddles (such as Euro blades versus Greenland paddles.) The first step was to create a method to calculate the stress on a paddle. The real world test using the sensor while paddling on the water validated the tests that Gearlab conducted in a controlled laboratory setting since the results were similar.

What will this mean to Gearlab as it communicates to the consumer?

This process will allow Gearlab to test their paddles in another manner before sending them to the consumer. While this has not been a problem in the past, Gearlab will have a more definitive metric to test their paddles against to ensure that each paddle manufactured performs superiorly for consumers. In addition, establishing a universal metric for paddle companies will allow Gearlab to quantify the superior strength of their paddles compared to competitors’ products.

What are different improvements and advancements that you can look forward to in additional testing?

Moving forward, the goal is to continue to refine the testing apparatus so the data is easier to analyze. One modification will be to program the Arduino to assign a time to each data point. This will allow us to sync the data to a video clip to see how the paddle reacts to different strokes. In addition, continued testing will help Gearlab confirm the maximum forces that the paddle experiences. One of the major assumptions made with this project was to test the paddle in ideal paddling conditions. This was done to eliminate other potential variables, and to make it easy to troubleshoot the sensor if anything went wrong. However, often times these paddles are used in rough water conditions with significant waves and currents. Therefore, future tests will include using the paddle in a variety of different weather conditions to calculate how the forces on the paddle change.